SK H2O was founded in 2003 with the aim of offering innovative and customised solutions in the field of elastomer sealing for engineering and construction projects.

In 2004, the production of sealing systems consisting of elastomer profiles using the latest autoclave, injection moulding and pressing technologies, began at the Rhede site and has been further developed here. Effective restructuring measures in 2015 have significantly increased productivity and enabled us to meet the market demand for sealing systems.

Over the years, apart from elastomers conforming to DIN 7865 specifications, we started producing thermoplastic profiles conforming to the factory standard and DIN 18541, so that our portfolio now covers the entire range of waterstop sealing solutions.

Our staff are trained in vulcanising and welding techniques and receive ongoing training. In-house training of young, committed and experienced employees ensures that a strong and motivated team of around 15 vulcanisers is at your disposal, ready to respond to your requirements at any time. Our employees also have in-depth knowledge of the installation of waterstop systems. So, whether it involves connecting new and existing structures or providing training in construction and expansion joints, they can help you on site as well.

The sealing of joints between existing and new structures has recently become especially significant. We're happy to serve you as a competent partner in this field.

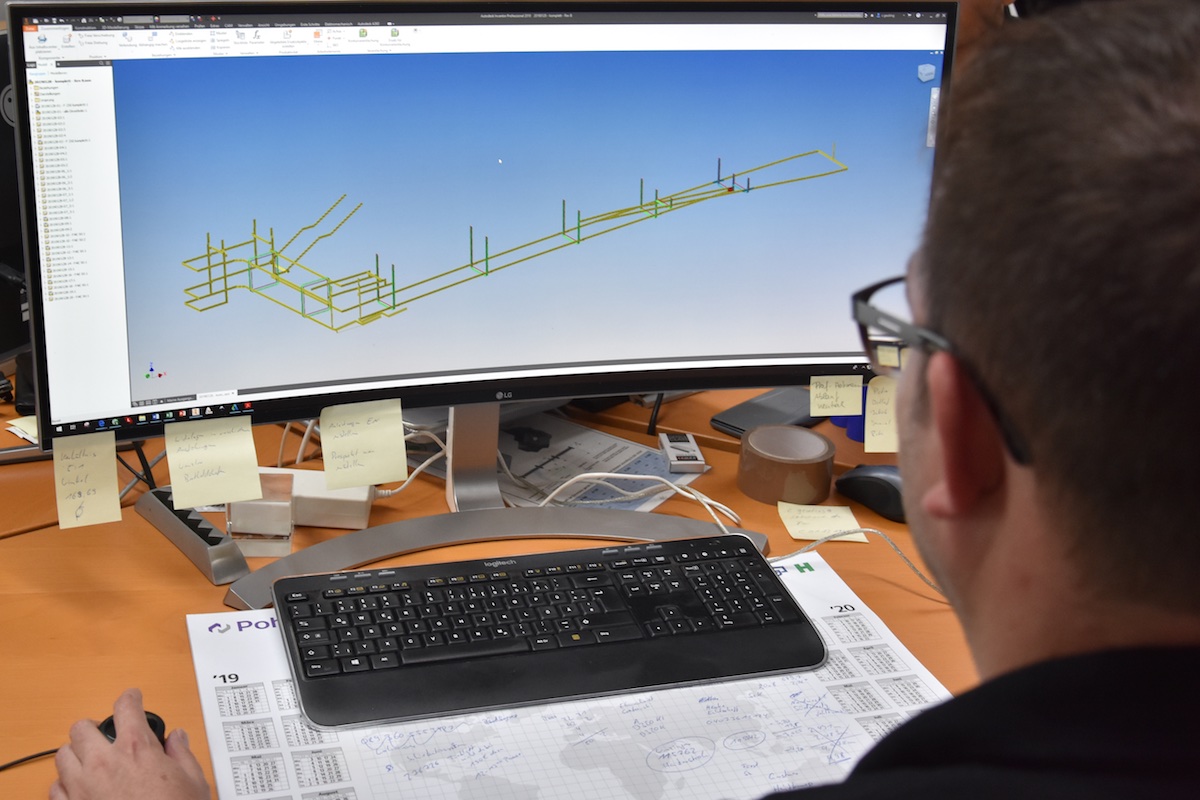

With qualified project management and ongoing consultation, we have been able to solve many difficult tasks and plan and deliver suitable systems for underground car parks, dams, sluices, ship canal lifts, tunnels, railway stations and more. We have a team of experienced employees at your disposal in these areas as well.

We have also been active in the international market for some time. We are no strangers to planning, production and logistics.